New Publication: Glancing Angle Deposition in Gas Sensing (Nanomaterials 2025, 15(14), Article 1136)

- Yiping Zhao

- Aug 6, 2025

- 2 min read

We’re excited to share our latest review article published in Nanomaterials, titled:👉 “Glancing Angle Deposition in Gas Sensing: Bridging Morphological Innovations and Sensor Performances”Read it here: https://www.mdpi.com/2079-4991/15/14/1136

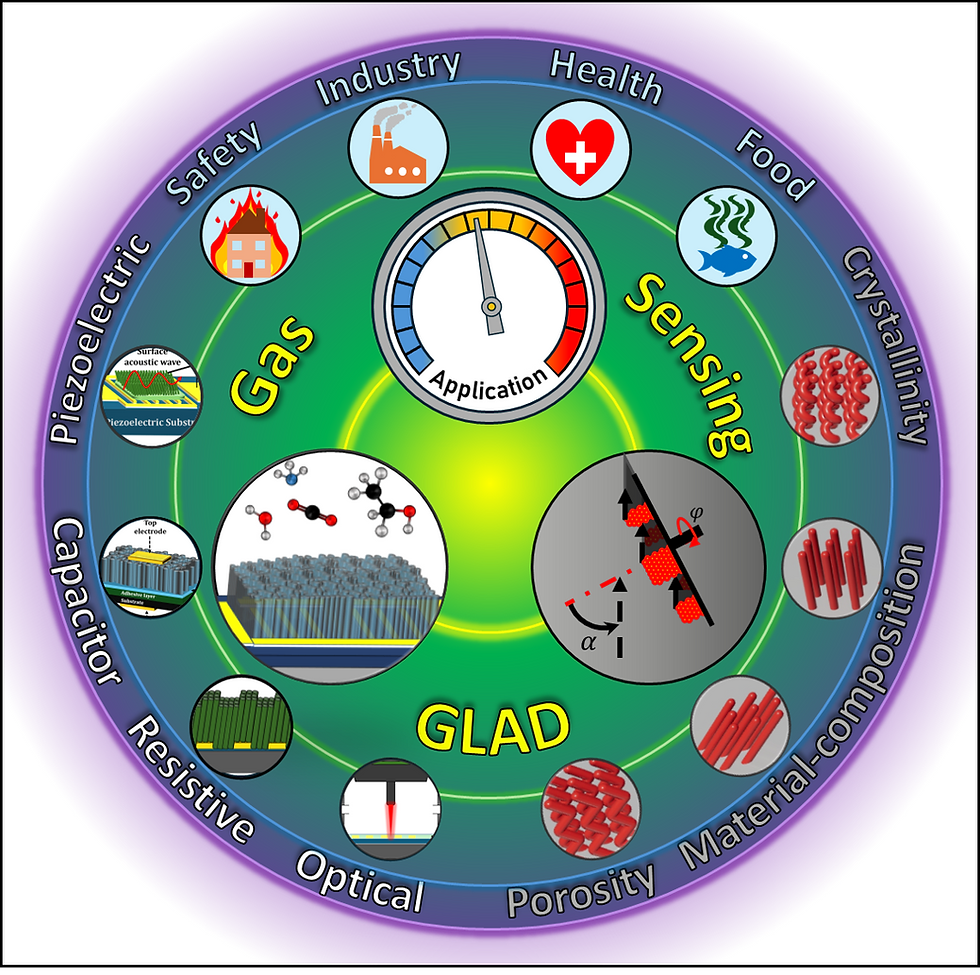

This comprehensive review explores how Glancing Angle Deposition (GLAD) is reshaping the design and functionality of nanostructured gas sensors. By enabling precise control over surface architecture and porosity, GLAD has opened new pathways for tailoring material properties, enhancing analyte interactions, and optimizing sensor performance across a wide range of platforms.

🔍 Why It Matters

Gas sensing plays a critical role in fields ranging from environmental monitoring to health diagnostics and industrial safety. However, achieving high sensitivity, selectivity, and rapid response remains a challenge—especially for low-concentration or multi-gas environments.

Our review highlights how GLAD enables:

Tailored nanostructure morphologies for enhanced surface-to-volume ratios

Porous, anisotropic films that improve gas adsorption and diffusion

Versatile integration into resistive, capacitive, optical, and piezoelectric sensing modalities

🧠 Main Contents

GLAD offers a bottom-up nanofabrication strategy that can create a rich variety of 3D nanostructures—including vertical nanorods, helical pillars, and zigzag columns—by manipulating substrate tilt and rotation during physical vapor deposition.

In this review, we:

Classify GLAD-fabricated gas sensors based on geometry, material systems, and sensing principles

Analyze the effects of material doping, decoration, and hybrid architectures on gas detection

Explore emerging trends in multimodal sensing, flexible substrates, and wearable platforms

📈 Structure–Performance Insights

Vertical and tilted nanorods provide directional porosity and fast gas transport

Metal oxide semiconductors (MOS) and noble metal nanoparticles enhance charge transfer and catalytic activity

Multilayer and core–shell architectures enable tunable selectivity and dynamic range

Functionalized GLAD structures can respond to VOCs, toxic gases (e.g., NO₂, NH₃), and even biomarker gases at sub-ppm levels

These design strategies are directly correlated with sensor metrics such as response time, recovery time, limit of detection (LOD), and signal stability.

💡 What Sets This Work Apart

While GLAD has been widely used in photonics and surface engineering, its systematic application to gas sensing remains underexplored. Our work:

Provides a framework to connect nanostructure geometry with gas sensor function

Identifies key opportunities for multi-gas detection using tailored GLAD morphologies

Emphasizes the role of AI and data-driven design in optimizing sensor architectures

🔬 Applications and Materials Reviewed

We cover a wide range of materials and sensing targets:

MOS nanostructures: ZnO, SnO₂, WO₃, TiO₂

Metal-decorated systems: Pt-, Pd-, Au-decorated sensors

Organic/inorganic hybrids: MOFs, polymers, carbon-based coatings

Target gases: NO₂, H₂S, NH₃, CO, VOCs, acetone, ethanol, etc.

Our analysis integrates both fundamental material design and real-world sensing performance, offering readers a bridge between fabrication science and practical device engineering.

🔭 Looking Ahead

This review lays the groundwork for next-generation GLAD-enabled gas sensors and suggests several future directions:

Coupling GLAD with ALD/CVD/plasma etching for hierarchical nanostructures

Developing multi-modal sensors combining optical and electrical outputs

Exploring AI-guided structure-property modeling and inverse design

Creating portable, flexible, and wearable sensor arrays for environmental and biomedical use

📌 Citation: Singh, S.; Stiwinter, K.C.; Singh, J.P.; Zhao, Y.Glancing Angle Deposition in Gas Sensing: Bridging Morphological Innovations and Sensor Performances.Nanomaterials 2025, 15(14), 1136.https://doi.org/10.3390/nano15141136

Let us know if you're working in this area or planning to integrate GLAD into your sensor designs—we’d love to connect!

Comments